Links:

One of the primary advantages of GRP water tanks is their resistance to corrosion. Unlike traditional steel or concrete tanks, GRP is immune to rust and degradation due to environmental elements. This characteristic is particularly important in regions with extreme weather conditions or high salinity levels that can harm conventional tanks. Additionally, GRP tanks are lightweight, which simplifies transportation and installation. Their modular design further allows for easy expansion, a crucial feature for growing facilities or communities.

Fibreglass, also known as fibreglass reinforced plastic (FRP), is a composite material made of fine glass fibers woven into a resin matrix. This combination results in a material that is not only lightweight but also exceptionally durable and resistant to corrosion, making it ideal for numerous environments, including those subject to harsh weather conditions or exposure to chemicals.

5. Reduced Carbon Footprint The production and utilization of FRP rebar contribute to a lower carbon footprint compared to traditional materials. As sustainability becomes increasingly important in construction, the eco-friendliness of FRP is a significant selling point.

Customization Options

Additionally, fiberglass fence posts have high tensile strength and can bear significant loads, making them ideal for security fences and agricultural applications. This strength means that they are less likely to bend or break under stress, ensuring that your fence remains intact and functional over time.

The versatility of pressure tanks allows their use across various fields. Here are some common applications

pressure tank

4. Environmental Impact By efficiently purifying water, industrial RO systems contribute to sustainable water management practices, promoting conservation and reducing water wastage.

Future advancements are likely to focus on improving the manufacturing processes of FRP bars, enhancing their mechanical properties, and developing new types of fiber composites. Additionally, research into the long-term performance of FRP-reinforced structures aims to provide engineers with a clearer understanding of how these materials behave over time, especially in challenging environmental conditions.

In today’s fast-paced construction industry, the demand for efficient and cost-effective building solutions is higher than ever. One such solution that has gained significant popularity is the use of prefabricated handrails. These pre-made railing systems offer a multitude of benefits that cater to both residential and commercial projects while ensuring safety, aesthetic appeal, and ease of installation.

- Material Compatibility The choice of material for clamps should be compatible with the type of grating being used and the environmental conditions of the installation site. For instance, in corrosive environments, stainless steel clamps may be preferred for their resistance to rust and degradation.

In conclusion, Pentair’s FRP tanks offer a robust, versatile, and environmentally friendly solution for a multitude of industrial applications. Their impressive features, including corrosion resistance, lightweight design, and long lifespan, make them a preferable choice over traditional tank materials. As industries continue to seek efficient and durable storage solutions, Pentair’s FRP tanks stand out as a reliable choice that combines innovation with practicality. Whether for water treatment, chemical storage, or agricultural use, these tanks will undoubtedly meet the diverse needs of today's market.

When considering FRP square tubes for your next project, it is essential to evaluate the pricing in relation to the factors outlined above. While it may be tempting to opt for the lowest cost option, balance this with considerations of quality, durability, and suitability for your specific application. Investing in high-quality FRP square tubes can lead to significant long-term benefits, including reduced maintenance costs and enhanced performance.

Versatility in Design

Applications of Aluminum Bar Grating

Once the larger particles are removed, the water undergoes sedimentation, where it is allowed to sit in large basins. During this time, heavier particles settle to the bottom, forming sludge that can be removed. The next step is often filtration, which can involve layers of sand, gravel, and activated carbon to further eliminate finer particles and chemical contaminants.

water treatment

Key Suppliers in the Industry

4. Mining and Heavy Industry In mining operations, where safety is a critical concern, floor grating clamps play an essential role in securing grating over walkways and access points to ensure worker safety.

floor grating clamps

Open steel floor grating represents a critical investment for various industries seeking durable, safe, and cost-effective flooring solutions. Its unique structure allows for the seamless integration of safety, practicality, and aesthetic appeal, making it an indispensable component in numerous applications. As industries continue to evolve, the demand for open steel floor grating is likely to grow, reinforcing its position as a mainstay in modern construction and design.

5. Ease of Maintenance The smooth surface of FRP tanks makes them easy to clean and maintain. Additionally, the material does not promote biological growth, which is a common concern in the storage of liquids.

fibre reinforced plastic tanks

3. Low Maintenance The durability of pultruded FRP grating results in low maintenance costs over its lifespan. Its resistance to wear and tear minimizes the need for frequent repairs or replacements, providing cost savings for businesses in the long run.

4. Market Demand and Supply The broader economic landscape also influences the pricing of FRP vessels. Fluctuations in supply and demand, driven by industry trends and market forces, can lead to variations in pricing. For example, a spike in demand due to environmental regulations or shifts towards sustainable practices can create a competitive market, driving prices up.

An RO filter system typically consists of several stages of filtration. The process begins with a pre-filter that removes larger particles, sediment, and chlorine, which can damage the RO membrane. After the pre-filtration stage, water passes through the RO membrane itself, where the majority of contaminants are removed.

5. Safety Checks Once the installation is complete, conduct a final safety check. Ensure that all panels are securely fastened, and inspect for any sharp edges or protruding fasteners. A thorough safety inspection can prevent potential injuries and liabilities.

Durability and Strength

One of the vital components that augment the functionality of FRP vessels is the multiport valve. A multiport valve executes the role of directing the flow of fluids to various pathways within a system, thus improving the process flow while minimizing the need for multiple valves. This single unit can facilitate multiple operations, such as filling, discharging, and diverting flows, with simplicity and efficiency. The use of a multiport valve not only streamlines operations but also reduces potential leak points, thereby enhancing system integrity.

frp vessel with multiport valve

4. Flexibility in Design The versatility of FRP materials allows for a wide range of design applications. FRP rods can be customized in terms of size, shape, and composition to meet specific engineering requirements. This flexibility enables architects and engineers to innovate and create complex structures that may not be feasible with traditional materials.

frp rod

Durability is another essential benefit of FRP stair systems. These materials exhibit remarkable resistance to environmental factors such as moisture, chemicals, and UV radiation. This resistance makes FRP ideal for both indoor and outdoor applications, particularly in industrial settings where exposure to harsh chemicals is common. Additionally, unlike traditional materials that can corrode or rust over time, FRP maintains its appearance and structural integrity, promising a longer lifespan with minimal maintenance.

Advantages of Using Reverse Osmosis Systems

- Industrial Applications Industries often require reliable water storage for processes, cooling, and emergency supply. GRP insulated tanks can provide a consistent and efficient solution.

4. Eco-Friendly As sustainability becomes more critical in today's construction practices, FRP trench drains offer an environmentally friendly option. The materials used can be sourced from recycled products, and their resistance to degradation reduces the need for frequent replacements and waste.

frp trench drain

A Whole House Reverse Osmosis System presents an excellent solution for homeowners seeking to improve their water quality. By providing comprehensive filtration that addresses a multitude of contaminants, not only does it ensure that household water is safe to drink, but it also enhances overall health and wellness. Investing in such a system can lead to significant long-term benefits, making it a wise choice for those committed to maintaining the best quality of life for their families. As water quality concerns continue to rise, Whole House RO Systems stand out as a reliable and effective solution for ensuring clean, safe, and great-tasting water throughout every facet of home life.

Moreover, water vessel filters contribute to environmental sustainability. By filtering contaminants from water sources, they play a vital role in preserving aquatic ecosystems. Polluted water can lead to the degradation of these ecosystems, affecting biodiversity and the overall health of our planet. Utilizing effective filtration systems helps protect these valuable resources for future generations.

Another notable aspect of FRP walkways is their safety features. Many FRP products are designed with non-slip surfaces, making them ideal for areas prone to wet conditions, such as waterfronts and parks. Additionally, their lightweight nature can contribute to safer installation processes, reducing the risk of injury for workers and users alike.

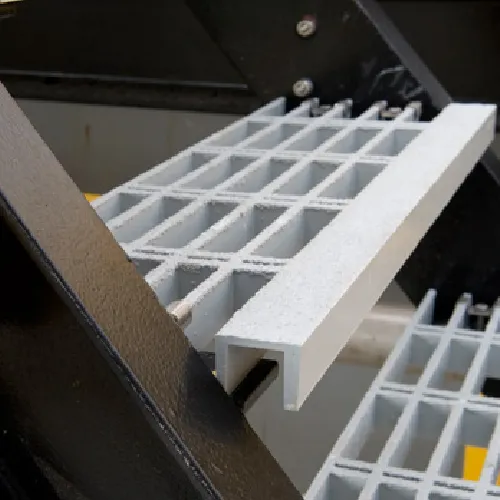

FRP grating is made from a composite material that consists of a thermosetting resin, such as polyester, vinyl ester, or epoxy, reinforced with fiberglass strands. Its primary benefits include high strength-to-weight ratio, resistance to chemical and environmental damage, and a non-slip surface. These qualities make FRP grating ideal for industrial settings, walkways, marine environments, and even architectural projects.

2. Lightweight yet Strong GRP grating is significantly lighter than metal alternatives, making it easier to handle and install. Despite its lightweight nature, GRP grating maintains impressive load-bearing capabilities, which makes it suitable for heavy-duty applications, including walkways, platforms, and grating over pits.

grp open mesh grating

1. Improved Appliance Longevity Softened water reduces the buildup of scale in appliances like dishwashers and water heaters, extending their lifespan and maintaining efficiency.

The advent of FRP pultruded sections marks a significant shift in construction materials, driven by the need for innovative, sustainable, and efficient solutions. With their unique properties and versatility, FRP materials are shaping the future of engineering and design. As industries continue to embrace these advanced materials, the potential applications and benefits of FRP pultruded sections are set to expand, paving the way for safer, more durable, and environmentally friendly structures.

2. Structural Integrity The integrity of flooring systems in industrial environments is a critical concern. Floor grating clamps contribute to the overall structural soundness of the grating system. By distributing weight evenly and preventing deformation, these clamps help maintain the longevity of the grating, ultimately protecting investments in infrastructure and equipment.

One prominent application of composite gratings is in advanced spectrometers. Traditional spectrometers rely on simple gratings to disperse light into its constituent wavelengths. However, composite gratings can enhance the resolution and sensitivity of these devices, allowing for more accurate identification of spectral lines. This is particularly beneficial in fields such as astronomy, environmental monitoring, and medical diagnostics, where precise spectral analysis is crucial.

The model number “1665” typically refers to the design specifications or capacity of the vessel, making it essential for buyers to understand that pricing may vary based on these specific features and the intended application

.As the global population continues to grow and water scarcity becomes an increasing concern, the importance of efficient water storage solutions cannot be understated. GRP panel water tanks offer a remarkable blend of durability, cost-effectiveness, and adaptability that makes them an excellent choice for diverse storage needs. Their ability to withstand environmental stresses while providing safe and hygienic water storage positions them as a favorable option for both current and future water management strategies. By investing in GRP panel water tanks, individuals and organizations can contribute to sustainable water use and management practices, ensuring a more reliable water supply for the future.

Applications of FRP Softener Vessels

2. Lightweight FRP sectional water tanks are considerably lighter than their concrete or steel counterparts, making transportation and installation easier. Their lightweight nature allows for flexible design and installation options, enabling them to be placed in various locations without the need for heavy machinery.

Fiber Reinforced Polymer (FRP) grating is an innovative and durable solution widely used in various industries, including construction, marine, and chemical processing. As industries increasingly focus on sustainable materials and improved safety features, FRP grating stands out due to its unique properties and advantages.

In addition to their superior functionality, Pentair FRP tanks also come equipped with various monitoring and control systems, which allow users to keep track of internal conditions and manage water levels effectively. This technological integration is part of Pentair's commitment to providing advanced, user-centric solutions that contribute to smarter water management practices.

What are Modular Stair Railing Systems?

In summary, Circular Hollow Section steel stands out as a vital material in modern construction and engineering due to its combination of strength, versatility, and aesthetic appeal. As industries continue to innovate and prioritize sustainable practices, CHS steel is expected to play an increasingly important role in building the future. Whether for structural support or aesthetic enhancement, CHS steel offers unparalleled advantages that make it an indispensable element in contemporary construction.

4. Ion Exchange This process is often used to soften water or to remove heavy metals. It involves exchanging one ion for another, effectively reducing the concentration of unwanted ions in the water.

industrial water filter system

Despite their numerous advantages, it's essential to consider proper handling and installation protocols to ensure the longevity and effectiveness of fiber water tanks. Professional assessment of site conditions and adherence to manufacturer guidelines can mitigate potential issues such as structural stress or improper fittings.

In recent years, architectural design has increasingly prioritized versatility, safety, and functionality, especially in public spaces and commercial buildings. Among the various elements contributing to this modern architectural ethos is the modular handrail system. This innovative approach offers a blend of flexibility, aesthetic appeal, and ease of installation, making it an attractive choice for builders and designers alike.